Power Supply Unit

For military applications that need dependable and constant power, a power supply unit (PSU) for MIL-grade PS and UPS is a crucial component. This kind of PSU is ideal for usage in military vehicles, aircraft, and other essential systems because it is specially made to tolerate extreme temperatures and environmental adversity.

The primary features, advantages, technical requirements, customizability choices, compliance and certifications, applications, testing, and validation, as well as maintenance and support services for the PSU will all be covered in this article.

Features & Benefits of Power Supply

Wanted to cope with the harsh environment and high electrical requirements of military and avionics applications. UPS Systems use tough packaging technology and field-proven, high efficiency designs. While supplying a well-conditioned AC output to the load, this UPS will take a broad variety of input voltage and frequency values. The solution with the lowest profile and least weight in its power class is made possible by the use of lithium polymer batteries. It is created and built to adhere to a variety of military criteria. A DC output is an option, and power may also be drawn via a 28 Vdc military standard input.

Customization Options

To specifically address the requirements of clients’ MIL-grade PS and UPS applications, the PSU may be tailored. There are several output voltages, currents, and connection possibilities for customization. Through this customisation, the PSU is made specifically to fit the needs of each application, providing optimum efficiency and dependability.

We are aware of the difficult conditions that the operators in the defense industry face across the globe, including extreme cold, water, high heat, and humidity. Generators may need to operate without maintenance for several months. We provide military-grade UPS and generator solutions that can keep your essential systems running in the worst conditions.

Technical Specification

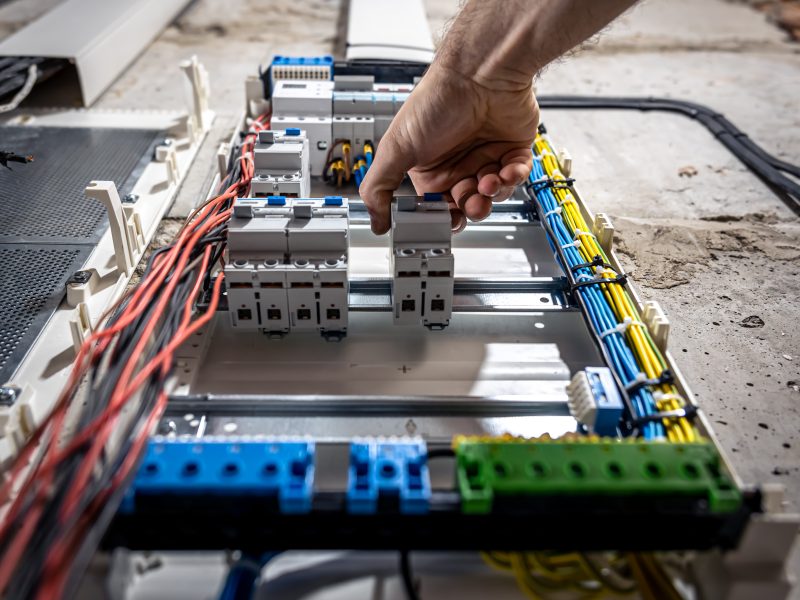

IEC 62040 should be followed in the design and construction of UPS. An indoor, floor-mounted, metal-enclosed panel with IP 42 enclosure protection should include all the components.

The UPS Cubicle needs to be dust- and vermin-proof, with an ambient temperature range of 50°C and a relative humidity band depending on the site conditions.

- Incoming MCCB in Inverter lines & By-pass lines.

- Input Isolation Transformer.

- Harmonic Filter.

- Rectifier / charger unit.

- Lead Acid sealed maintenance free Batteries.

- Inverter unit.

- Servo-controlled Voltage Regulator in the Bypass line.

- Automatic switching (Static Switch).

- Maintenance bypass switch.

- Protective devices and other accessories.

- 11. Control and Display Unit for monitoring of parameters and control of UPS.

Compliance and Certificate

Military power supplies are made to deliver dependable power in a variety of challenging settings, circumstances, and climates. One or more input standards, such as MIL-STD-704 for airplanes, MIL-STD-1399 for ships, and MIL-STD-1275 for land vehicles, must be met by a military power supply. Power supply must also satisfy any number of the environmental requirements listed in MIL-STD-810 or other comparable specifications in order to be deemed “rugged.” Continue reading to learn about seven military specifications for ruggedized power supply.

Seven Military Standards

A Power Supply Must Meet Seven Military Standards to Be Designed and Qualified.

MIL-STD-704 Aircraft Electric Power:

This standard establishes criteria for interoperability, operation, testing, and power usage of aviation power systems. It ensures that all aircraft utilization equipment is compatible with the airplane power system and external power.

MIL-STD-1399 Low Voltage Electric Power:

This standard specifies the electrical interface criteria for marine equipment, ensuring compatibility between user equipment and the electric power system on ships. It outlines the characteristics, tolerances, and test procedures for determining compatibility.

MIL-STD-1275 28 VDC Input Power to Military Vehicles:

This standard pertains to the electrical power distribution system for military ground vehicle platforms. It defines the operational voltage limitations and transient voltage properties of a 28-Vdc power supply, ensuring its ability to deliver regulated power under specified voltage transients.

MIL-STD-1275 28 VDC Input Power to Military Vehicles:

This standard pertains to the electrical power distribution system for military ground vehicle platforms. It defines the operational voltage limitations and transient voltage properties of a 28-Vdc power supply, ensuring its ability to deliver regulated power under specified voltage transients.

MIL-STD-810 Environmental Engineering Considerations:

MIL-STD-810 provides guidance for considering the effects of environmental conditions on ruggedized power supplies throughout their lifetime. It includes test procedures based on system performance criteria and environmental tailoring techniques for realistic product designs. Tests cover temperature, humidity, stress, vibration, and other factors.

MIL-STD-810 Environmental Engineering Considerations:

MIL-STD-810 provides guidance for considering the effects of environmental conditions on ruggedized power supplies throughout their lifetime. It includes test procedures based on system performance criteria and environmental tailoring techniques for realistic product designs. Tests cover temperature, humidity, stress, vibration, and other factors.

MIL-STD-461 Control of Electromagnetic Interference:

This standard specifies requirements for electromagnetic compatibility (EMC) and electromagnetic interference (EMI) for military power supplies. Compliance with MIL-STD-461 ensures satisfactory performance of equipment in a system by controlling and reducing EMI.

MIL-STD-461 Control of Electromagnetic Interference:

This standard specifies requirements for electromagnetic compatibility (EMC) and electromagnetic interference (EMI) for military power supplies. Compliance with MIL-STD-461 ensures the satisfactory performance of equipment in a system by controlling and reducing EMI.

MIL-STD-167 Mechanical Vibrations of Shipboard Equipment:

MIL-STD-167 outlines the methodology and requirements for testing the effects of vibration on shipboard equipment. It covers internal vibrations from gear as well as vessel-induced movements, ensuring equipment can withstand and function properly under various vibration spectra.

RTCA/DO-160 Environmental Conditions for Airborne Equipment:

This standard focuses on evaluating airborne equipment through environmental tests. It includes over 20 test types, such as vibration, shock, temperature, magnetic field, voltage spikes, and electrostatic discharge. Compliance with DO-160 ensures the reliability and performance of airborne power supplies.

RTCA/DO-160 Environmental Conditions for Airborne Equipment:

This standard focuses on evaluating airborne equipment through environmental tests. It includes over 20 test types, such as vibration, shock, temperature, magnetic field, voltage spikes, and electrostatic discharge. Compliance with DO-160 ensures the reliability and performance of airborne power supplies.

Testing And Validation

To make sure it satisfies all the requirements for MIL grade PS and UPS, the PSU goes through rigorous testing and validation procedures. These processes for evaluating the PSU’s effectiveness, dependability, and safety in various conditions include environmental testing, electromagnetic compatibility testing, and electrical safety testing.

Maintenance And Support

The PSU receives ongoing maintenance and support services, including as-planned maintenance, repair services, and technical assistance. These functions make sure that the PSU runs as reliably and efficiently as possible, minimizing downtime and maintenance expenses.